Laser etching and engraving refer to a permanent mark that is made when a laser removes material from the surface of an object. This marking can be done on almost any part, making it a great solution for traceability in a variety of industries. At White Elephant we use a CO2 lasers. CO2 lasers can cut and engrave the widest range of materials, such as plastics, wood, paper, fabric, acrylic, rubber and cardboard. Our CO2 lasers can also engrave on glass, ceramic, stone, and coated metals such as anodized aluminum or coated metals.

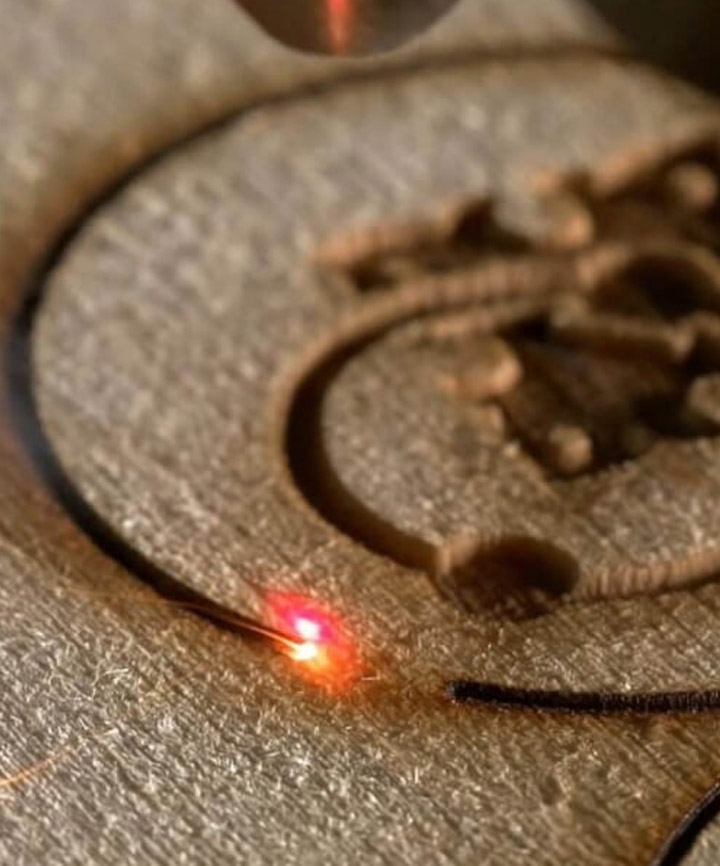

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications, but is also starting to be used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated. A commercial laser for cutting materials involved a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. Our CO2 Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.

With our rotary engraving attachment, we can use our Speedy laser engraver to process tumblers, cups, vases, bottles and glasses of various sizes and diameters. When the rotary engraving attachment is inserted, the axis movement in the Y direction is replaced by a rotary movement. With the special roll attachment, we can even process objects with large or small openings that do not fit into the cones of the standard configuration.